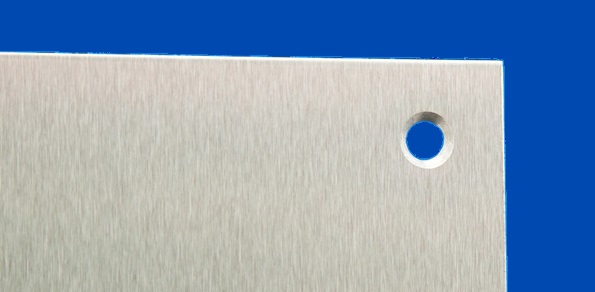

As the UK’s leading kick plate supplier, we are frequently asked about the standard procedure for drilling and countersinking our products.

What is the standard drilling for kicking and finger plates?

At SGS we have a high volume production line for manufacturing kicking and finger plates quickly and accurately. We employ a combination of traditional methods and modern machinery to produce items precisely to customer specifications.

If you would like holes drilling and countersinking in specific places, don’t hesitate to let our sales team know.

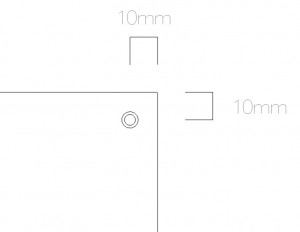

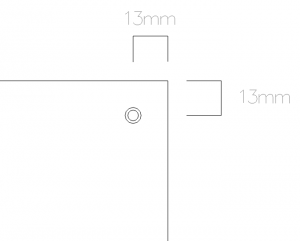

Below is a guide to the standard drilling procedure for kicking and finger plates;

Finger Plates

Up to 349mm 4 holes

350mm to 600mm 6 holes

601mm to 999mm 8 holes

1000mm to 1600mm 10 holes

Kicking Plates

Up to 400mm 4 holes

401mm to 600mm 6 holes

601mm to 999mm 8 holes

1000mm to 1599mm 10 holes

1600mm + 12 holes

Screws

And finally, all our kicking and finger plates are punched and countersunk for a 6 gauge screw. We can of course, drill and countersink to accommodate other screw sizes.